Introduction to Wind Energy

Colin Palmer

40 years: Renewable energy

Energy from the wind has been used by mankind for thousands of years, but has become outdated since the early twentieth century. Join Colin as he explains why there was a revival in wind energy in the 1907s and how the industry developed. He further talks about the square-cube law and its relevance to wind turbines.

Energy from the wind has been used by mankind for thousands of years, but has become outdated since the early twentieth century. Join Colin as he explains why there was a revival in wind energy in the 1907s and how the industry developed. He further talks about the square-cube law and its relevance to wind turbines.

Introduction to Wind Energy

15 mins 43 secs

Key learning objectives:

Why was there a revival in wind energy in the 1907s?

How did the industry develop?

What has become the industry standard design, and why?

What is the square-cube law and why is it relevant to wind turbines?

Overview:

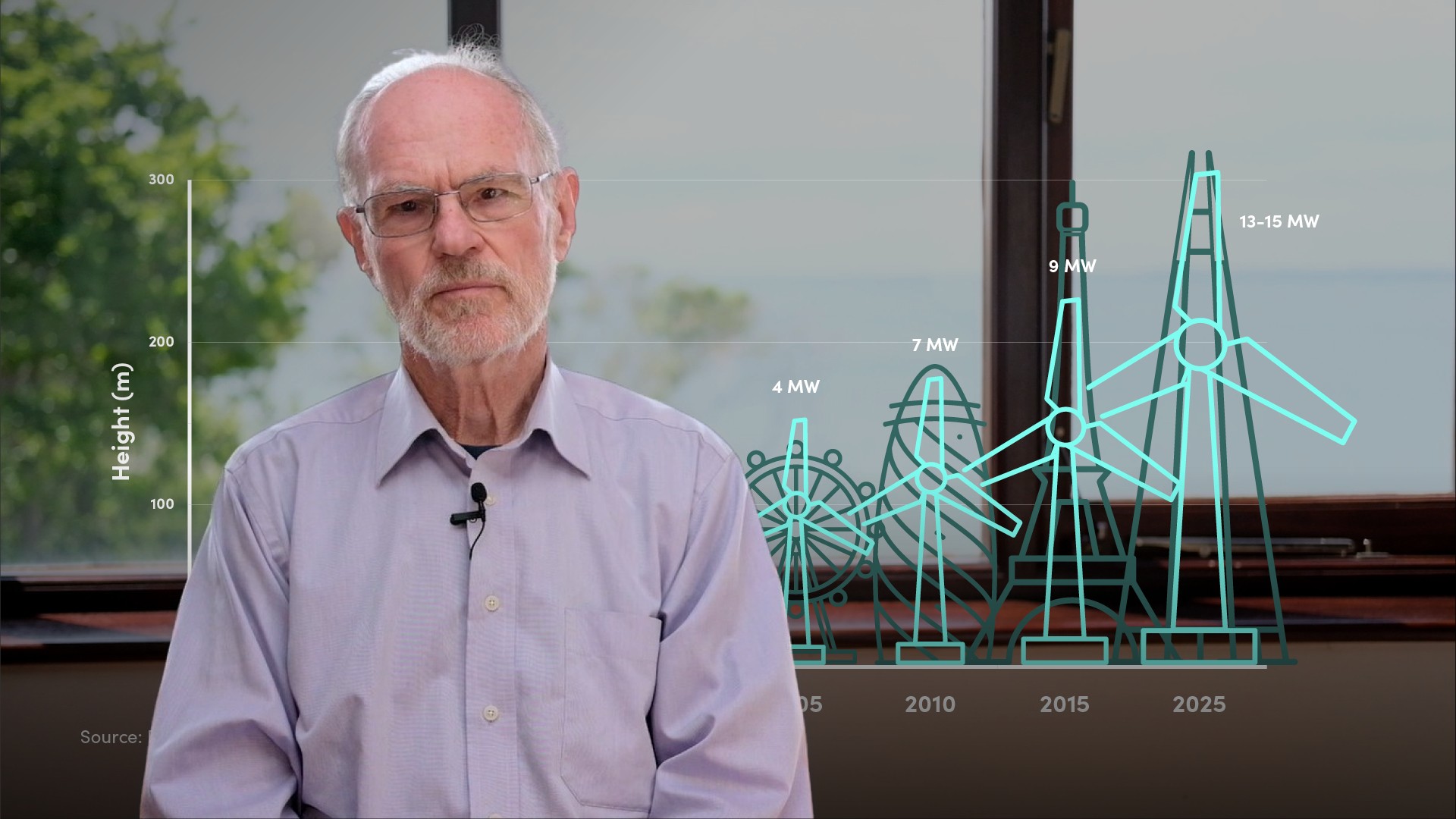

Energy from the wind has been used by mankind for thousands of years, but had become outdated by the early twentieth century. It needed the oil price shock of the mid 1970s to renew interest in this technology, and by the 80s there were thousands of new wind turbines in operation, mainly in Europe and the USA. After considerable government backed research and commercial development, the industry settled on the “Danish model” design, with three blades made of composite materials, rotating on the upwind side of a steel tower. Over time the average size of wind turbines increased, from around 30m diameter in the early 1980s to as much as 240m today. Power output has increased from 350kW to 15MW. The cost of wind turbines has reduced over time and continues to do so. In many parts of the world, electricity from wind turbines is now competitive with fossil fuel generation.

Why was there a revival in wind energy in the 1970s?

In the mid 1970s OPEC suddenly increased the price of oil. Developed economies were made painfully aware of their reliance on oil (and other fossil fuels) so embarked on programmes to develop alternative sources of energy. Denmark, Germany and the USA in particular focussed on wind energy development, which was supported with a variety of grant and market incentive schemes.

How did the industry develop?

Initially in the USA and Germany the industry was driven by large scale, government backed R&D programmes. Meanwhile, in Denmark the focus was on small-scale local developments, based on pre-existing turbine designs. In the early 80s, the USA introduced market based incentives, resulting in a “wind rush” period of exponential growth and a great deal of private sector design innovation. By the 1990s, the industry settled down into a process of design standardisation and commercial consolidation. Danish companies emerged as market leaders, both in terms of successful companies and the widespread adoption of the “Danish model” of three-bladed upwind turbine design. Danish companies held their market lead into the 21st century, but are increasingly challenged by American and German companies, and most recently, the Chinese.

In recent years there has been some divergence in turbine designs. Machines for onshore installations are tending to be limited to around 150m in diameter, in part due to transport logistics but also cost pressures. For offshore turbines, the size is still increasing, with 20MW, 270m diameter machines likely within the next few years.

Since the late 90s, wind turbines have been a sufficiently mature technology to attract project finance, and, with increasing experience and maturity, risk premia have dropped, contributing the the reduction in the cost of energy.

What has become the industry standard design, and why?.

In the early days of government backed research programs, large, two bladed down-wind machines were considered to be the most promising development path. Blade materials investigated included steel, aluminium and composite materials, with towers of steel or concrete. None of the machines entered series production. Meanwhile, the nascent Danish commercial wind turbine industry was developing what became known as the “Danish model” - machines with three blades made from composite materials, positioned on the upwind side of a steel tower. Power was transmitted via a gearbox to a conventional electricity generator. The Danish industry started small and largely “learnt by doing”, making incremental increases in size and improvements in technology.

By late 1990s, production wind turbines were all of this type and manufactured by companies in many countries. This created a technological path dependence which appears likely to continue to dominate the onshore wind turbine designs, were economies of scale are a key driver. It may be disrupted in the offshore designs, where the returns to innovation may prove sufficient to justify high investment in new design concepts.

What is the square-cube law and why is it relevant to wind turbines?

A fundamental characteristic of physical object is that as they grow larger the ratios of different proportions change. For example, consider a cube with sides that are one unit long. The area of each face is therefore one square unit and the volume is one cubic unit. If the cube is made twice as large (with sides two units in length), the area of each side becomes four square units and the volume eight cubic units. If the cube is solid, this means that the twice sized cube weighs eight times as much (it increases as the third power of scale).

For physical structures, the strength and stiffness characteristics are generally related to the cross sectional area of components, whereas the loads are related to volume (weight). This means that, unless the properties of the materials are changed, larger structures have to be more robust than smaller ones. It is for this reason that elephants are not the same shape as mice - a mouse scaled directly to the size of an elephant would be impossibly weak.

For wind turbines, the loads therefore tend to increase to the third power of size, whereas the power output (and strength) vary as the square. This means that the larger they become, the more that wind turbines are adversely affected by the square cube law. Since the total cost of a wind energy project is more than the cost of the turbines alone (much more in the case of offshore wind energy) there is theoretically an optimum size of turbine for any particular project.

It was once thought that turbines of around 40m in diameter were the optimum for onshore sites, but over time manufacturers managed to beat the square cube law by design refinements and the introduction of higher performance materials. In practice the weight of wind turbine blades has only increased as the square of size, and this flows through to other components in the structure, with the result that the optimum size for onshore wind turbines now appears to be somewhere between 2MW and 6MW (120m to 150m diameter). For offshore wind turbines, where non-turbine costs are a higher proportion of project cost, it appears that the upper limit to size has yet to be reached.

Colin Palmer

There are no available Videos from "Colin Palmer"